What is Full Depth Reclamation?

Full depth reclamation is a method of road construction that involves the recycling of existing materials to create a new road surface. It is a cost-effective and sustainable alternative to traditional methods of road repair and construction.

Unlike traditional methods, which require the removal and disposal of the existing road surface, full depth reclamation involves pulverizing the existing road materials, including the pavement and base, and mixing them with a stabilizing agent, such as cement or lime. This mixture is then compacted to create a new road surface.

The process of full depth reclamation not only reduces the need for new materials, but also eliminates the costs and environmental impacts associated with disposal of the old road materials. It also results in a more durable road surface that can withstand heavy traffic and adverse weather conditions.

In addition to its environmental and cost benefits, full depth reclamation is also a faster method of road construction compared to traditional methods. The pulverization and mixing of the existing materials can be done quickly, and the new road surface can be opened to traffic within a short period of time.

What is Full Depth Reclamation?

Full depth reclamation is a road construction technique that involves pulverizing the existing pavement and mixing it with additives to create a stabilized base for a new road surface. This process is commonly used to rehabilitate deteriorating roads and restore their structural integrity.

During full depth reclamation, a specialized machine called a reclaimer is used to pulverize the existing pavement to a predetermined depth. The pulverized material is then mixed with additives, such as cement, lime, or asphalt emulsion, to enhance its stability and strength. The mixture is then compacted to form a new base layer, which serves as the foundation for the new road surface.

Full depth reclamation offers several advantages over traditional road construction methods. Firstly, it is a cost-effective solution as it eliminates the need to completely remove and replace the existing pavement. This reduces the amount of materials and labor required, resulting in significant cost savings. Additionally, full depth reclamation is an environmentally friendly option as it reduces the need for new materials and minimizes waste generation.

Furthermore, the use of additives in the reclamation process allows for the customization of the stabilized base to suit specific engineering requirements. The choice of additives can improve the durability, flexibility, and load-bearing capacity of the base layer, ensuring the longevity and performance of the new road surface.

In conclusion, full depth reclamation is a road construction technique that involves pulverizing the existing pavement and incorporating additives to create a stable base layer for a new road surface. It offers cost-effective and environmentally friendly benefits while allowing for customization to meet specific engineering requirements.

Definition and Explanation of Full Depth Reclamation

Full Depth Reclamation (FDR) is a construction technique used to rehabilitate and strengthen deteriorating pavement structures. It involves the process of pulverizing the existing pavement and mixing it with an additive material to create a new base for the road. This cost-effective and sustainable method is used to improve the overall structural capacity of the pavement.

During the full depth reclamation process, the existing pavement is pulverized using heavy machinery, such as a reclaimer or milling machine. This mechanical action breaks up the asphalt and any underlying layers into small granular particles. The pulverized material is then mixed with a binding agent, typically cement, lime, or asphalt emulsion, and compacted to form a new base layer.

There are several advantages to using full depth reclamation. Firstly, it eliminates the need for costly and time-consuming pavement removal and replacement. By recycling the existing materials, it reduces the amount of waste generated and decreases the demand for new aggregate. Additionally, the new base layer created through full depth reclamation has improved strength and durability, resulting in a longer lifespan for the pavement.

Full depth reclamation is typically used for roads and parking lots with significant distresses, such as rutting, cracking, and potholes. It can be applied to both asphalt and concrete pavements, making it a versatile solution for various types of road infrastructure.

In summary, full depth reclamation is a construction technique that involves pulverizing and mixing the existing pavement with an additive material to create a new base layer. This method offers cost savings, environmental benefits, and improved pavement longevity, making it an attractive option for pavement rehabilitation projects.

Benefits of Full Depth Reclamation

Full Depth Reclamation (FDR) is a cost-effective method of pavement rehabilitation that offers several benefits. Here are some of the key advantages of using FDR:

- Durability: FDR creates a strong, long-lasting pavement structure. The process stabilizes the existing materials and improves their load-bearing capacity, reducing the need for future repairs or replacement.

- Environmentally Friendly: FDR is an environmentally sustainable solution. It recycles existing materials, minimizing the need for new aggregates and reducing waste. This makes FDR a greener alternative to traditional pavement construction methods.

- Cost Savings: FDR is a cost-effective option for pavement rehabilitation. By reusing existing materials, the need for new aggregates and other resources is reduced, resulting in significant cost savings. Additionally, FDR reduces future maintenance and repair costs due to its durable nature.

- Time Efficiency: FDR is a time-efficient process. It can be completed quickly, minimizing the disruption to traffic and reducing the overall project timeline. This makes it an ideal choice for projects where minimizing downtime is a priority.

- Improved Performance: FDR improves the performance of pavement structures. By stabilizing the existing materials, it enhances the pavement’s strength, flexibility, and resistance to cracking, rutting, and other forms of distress.

In summary, Full Depth Reclamation offers a range of benefits, including durability, environmental friendliness, cost savings, time efficiency, and improved pavement performance. It is a reliable and sustainable pavement rehabilitation method that should be considered for various road construction projects.

Process of Full Depth Reclamation

Full Depth Reclamation (FDR) is a process used to restore and strengthen existing roadways. It involves pulverizing the existing pavement, mixing it with a stabilizing agent, and compacting it back into a new base layer. This process is cost-effective and environmentally friendly, as it reduces the need for new materials and minimizes waste.

The process of Full Depth Reclamation can be summarized in the following steps:

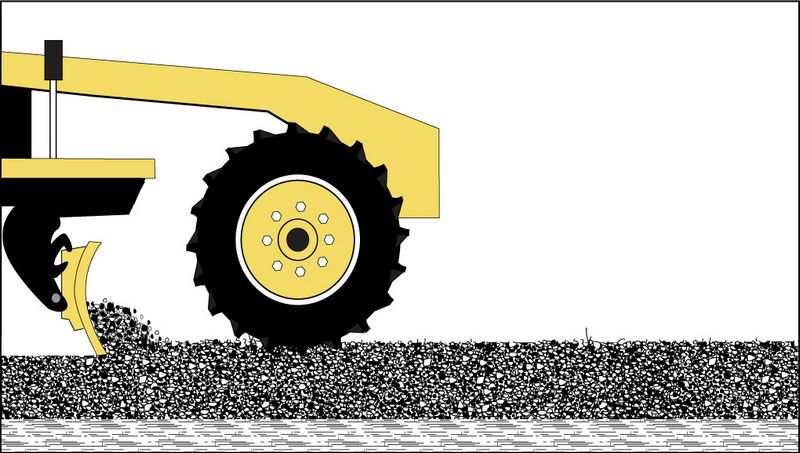

- Pulverization: The existing pavement is pulverized using a special machine called a reclaimer. This machine grinds the pavement into small pieces, creating a base for the new layer.

- Stabilization: A stabilizing agent, such as cement or lime, is added to the pulverized pavement. This agent helps to bind the materials together and improve the strength of the base layer.

- Blending: The stabilization agent is thoroughly mixed with the pulverized pavement. This process ensures that the stabilizing agent is evenly distributed, resulting in a uniform and strong base layer.

- Compaction: The blended mixture is then compacted using heavy machinery. This compaction process ensures that the base layer is dense and stable, capable of supporting heavy traffic loads.

- Finishing: Once the base layer is compacted, it is typically covered with a layer of asphalt or concrete to provide a smooth riding surface. This additional layer increases the durability and longevity of the road.

The Full Depth Reclamation process is commonly used for road rehabilitation projects, as it allows for the efficient and economical restoration of existing roadways. By recycling the existing pavement, FDR reduces the need for new materials and minimizes construction waste, making it an environmentally friendly solution for road maintenance.

Materials Used in Full Depth Reclamation

In full depth reclamation (FDR), there are several materials that are commonly used to achieve the desired results. These materials play a crucial role in the overall process and help to create a strong and durable road surface.

Some of the materials used in full depth reclamation include:

- Asphalt: Asphalt is one of the primary materials used in full depth reclamation. It is a versatile and durable material that helps to bind the various layers of the road together. Asphalt provides structure and stability to the reclaimed road surface.

- Cement: Cement is another commonly used material in full depth reclamation. It acts as a stabilizing agent and helps to increase the strength and durability of the reclaimed road. Cement also helps to improve the load-bearing capacity of the road.

- Water: Water is an essential component in the full depth reclamation process. It is used to mix the various materials and create a homogeneous mixture. Water also helps to activate the binding properties of asphalt and cement, ensuring a strong and durable road surface.

- Aggregate: Aggregate refers to a mixture of sand, gravel, and crushed stone. It is used to provide texture and stability to the reclaimed road surface. The aggregate helps to improve the drainage properties of the road and prevent the accumulation of water.

- Chemical Additives: Chemical additives are sometimes used in full depth reclamation to enhance the properties of the materials. These additives can include polymers, adhesion promoters, and curing agents. They help to improve the bond between the various layers and increase the overall strength of the road.

By combining these materials in the right proportions, full depth reclamation can effectively rehabilitate old and deteriorated roads. The use of these materials helps to create a sustainable and long-lasting road surface that can withstand heavy traffic and harsh weather conditions.

Equipment Needed for Full Depth Reclamation

In order to perform full depth reclamation, several pieces of equipment are necessary. These tools help ensure that the process is completed effectively and efficiently.

1. Reclaimer: The reclaimer is the main piece of equipment used in full depth reclamation. It is a large machine that is capable of pulverizing existing pavement and mixing it with additives such as cement or asphalt emulsion. The reclaimer is equipped with rotating drums or blades that break up the old pavement and mix it with the additives to create a new base material.

2. Water Truck: A water truck is used to apply water on the reclaimer during the process. This helps to control dust and keep the machine running smoothly. The water truck is essential for maintaining the proper moisture content in the reclaimed material.

3. Grader: A grader is used to even out the reclaimed material after it has been mixed by the reclaimer. The grader helps to create a smooth and compacted surface that is ready for further construction.

4. Compact Roller: A compact roller is used to compact the reclaimed material and ensure that it is properly bonded. The roller applies pressure to the material, helping to eliminate any voids and create a strong base.

5. Sweeper: A sweeper is used to clean the surface before applying any new materials. It removes any loose particles or debris, ensuring a clean and smooth surface for further construction.

6. Paver: A paver is used to apply new asphalt or concrete on top of the reclaimed base. It helps to create a finished surface that is ready for traffic.

In addition to these main pieces of equipment, other tools such as trucks, loaders, and compactors may also be used during the full depth reclamation process. These tools help to transport materials, remove debris, and further compact the reclaimed base.

Overall, the equipment needed for full depth reclamation depends on the specific project and requirements. However, having the right tools and machinery is crucial for ensuring a successful and durable result.

Comparison to Other Road Construction Methods

When it comes to road construction, there are various methods that can be used. Full Depth Reclamation (FDR) is one such method. Let’s take a look at how it compares to other road construction methods:

- Asphalt Overlay: This method involves applying a new layer of asphalt on top of the existing road surface. While it provides a smooth and durable surface, it does not address underlying structural issues. FDR, on the other hand, not only improves the surface but also strengthens the entire road section.

- Mill and Overlay: Milling and overlaying is another common method where the top layer of the existing road is removed and replaced with a new layer of asphalt. This method is effective for fixing surface distresses but does not address deeper structural problems. FDR, with its process of pulverizing and mixing the existing pavement, provides a more comprehensive solution.

- Full-Depth Reconstruction: Full-depth reconstruction involves completely removing the existing road and building a new road from scratch. It is a time-consuming and expensive process. FDR, on the other hand, offers a cost-effective and time-efficient alternative as it reuses the existing materials and minimizes the need for new construction.

In conclusion, Full Depth Reclamation (FDR) offers several advantages over other road construction methods. It not only improves the surface but also strengthens the underlying structure, provides a cost-effective solution, and minimizes the need for new construction. This makes it a desirable option for road rehabilitation projects.

Factors Influencing the Success of Full Depth Reclamation

In order to achieve a successful full depth reclamation project, several factors must be taken into consideration. These factors can greatly influence the outcome and durability of the reclamation process. Here are some key factors that play a crucial role in the success of full depth reclamation:

- Depth: The depth of the existing pavement or base material being reclaimed is an important factor. The depth should be sufficient to allow for proper stabilization and compaction.

- Full Depth: The decision to perform full depth reclamation, rather than partial depth reclamation, can also affect the success of the project. Full depth reclamation involves removing all layers of the existing pavement and base material before adding new materials.

- What Materials Are Being Reclaimed: The type and condition of the materials being reclaimed can impact the success of the reclamation process. Different materials may require different stabilization techniques or additives.

- Reclamation Technique: The chosen reclamation technique can also influence the success of the project. Common techniques include mechanical pulverization, chemical stabilization, and foamed asphalt stabilization.

- Compaction: Proper compaction of the reclaimed materials is critical for achieving long-lasting results. Insufficient compaction can lead to settlement and premature deterioration.

- Climate and Weather Conditions: The climate and weather conditions during and after the reclamation process can impact the success of the project. Extreme temperatures, rainfall, or freezing/thawing cycles can affect the performance of the reclaimed materials.

- Quality Control: Implementing quality control measures throughout the reclamation process is essential. Regular testing and inspection of materials, compaction, and stabilization techniques can help ensure a successful outcome.

By considering these factors and making informed decisions, the likelihood of a successful full depth reclamation project can be greatly increased. It is important to consult with experienced professionals and follow industry best practices for optimal results.

Environmental Impact of Full Depth Reclamation

Full Depth Reclamation (FDR) is a pavement rehabilitation technique that involves pulverizing existing asphalt or concrete pavement materials and incorporating them into the newly constructed pavement base. While FDR is an effective and cost-efficient method of rehabilitating roads, it is important to consider its environmental impact.

One of the main environmental benefits of FDR is its ability to recycle existing materials. By reusing the pavement materials, FDR reduces the need for new aggregate and asphalt, thus conserving natural resources. This also helps to reduce the energy consumption and emissions associated with the production and transportation of new materials.

FDR also promotes sustainability by minimizing waste generation. Instead of removing and disposing of old pavement materials, FDR recycles them, reducing the amount of waste sent to landfills. This not only saves valuable landfill space but also reduces the environmental impact of waste disposal.

Another environmental advantage of FDR is its potential to improve the pavement’s durability and longevity. By incorporating the old pavement materials into the new base, FDR creates a stronger and more resilient road surface. This can reduce the need for future maintenance and repairs, thus minimizing the environmental impact associated with road construction and maintenance activities.

However, it is important to consider potential negative environmental impacts of FDR as well. The pulverization process can create dust and particulate matter, which can contribute to air pollution if not properly controlled. Therefore, measures should be taken to minimize dust emissions during the FDR process, such as using water sprays or dust control agents.

In addition, the transportation of equipment and materials to and from the construction site can generate greenhouse gas emissions. It is important to optimize transportation routes and consider using low-emission vehicles to minimize the carbon footprint of FDR projects.

Overall, while Full Depth Reclamation has various environmental benefits such as recycling materials, reducing waste generation, and improving pavement durability, it is crucial to mitigate potential negative impacts such as air pollution and greenhouse gas emissions. By implementing proper dust control measures and optimizing transportation, the environmental impact of FDR can be minimized.

Cost Analysis of Full Depth Reclamation

Full Depth Reclamation (FDR) is a cost-effective method of rehabilitating asphalt pavement. This process involves pulverizing the existing pavement and combining it with a binding agent to create a strong and durable base for new pavement. But what is the cost of Full Depth Reclamation, and how does it compare to traditional rehabilitation methods?

When considering the cost of Full Depth Reclamation, several factors should be taken into account:

- Materials: The cost of the binding agent and other materials used in the process can vary depending on the location and availability.

- Labor: The cost of labor for the pulverization and mixing processes is an important factor to consider. However, FDR typically requires less labor compared to traditional methods, which can help reduce costs.

- Equipment: The cost of equipment used for Full Depth Reclamation, such as pulverizers and mixers, should also be considered. However, this cost can be offset by the potential savings in labor and time.

- Time: FDR can be completed in a shorter time frame compared to traditional methods, which can help minimize traffic disruptions and reduce project costs.

- Maintenance: The long-term cost of maintaining the rehabilitated pavement should also be considered. FDR has been shown to result in durable and long-lasting pavement, which can reduce the need for frequent repairs and maintenance.

Overall, Full Depth Reclamation is often more cost-effective compared to traditional methods of pavement rehabilitation. While the initial cost may be higher due to the equipment and materials required, the long-term savings in labor, time, and maintenance can make FDR a cost-saving option in the long run.

| Materials | Varies | Varies |

| Labor | Lower | Higher |

| Equipment | Higher | Lower |

| Time | Shorter | Longer |

| Maintenance | Lower | Higher |

Overall, Full Depth Reclamation offers a cost-effective solution for rehabilitating asphalt pavement. By considering the factors mentioned above and comparing the costs to traditional rehabilitation methods, it becomes clear that FDR can provide long-term cost savings while still delivering a durable and high-quality pavement surface.

Case Studies of Successful Full Depth Reclamation Projects

Full depth reclamation is a cost-effective and sustainable method of rehabilitating old and deteriorating roads. Here are some case studies of successful full depth reclamation projects:

-

Case Study 1: Highway A Rehabilitation

Location: State X

Project Size: 10 miles of highway

Duration: 3 months

Results: The full depth reclamation process was applied to a crumbling highway in State X. The existing pavement was pulverized and blended with stabilizing agents. The reclaimed material was then compacted and overlaid with a new asphalt surface. The project resulted in a smooth and durable road with improved drainage. The full depth reclamation process saved time and money compared to traditional reconstruction methods.

-

Case Study 2: City B Streets Rehabilitation

Location: City B

Project Size: 20 city streets

Duration: 6 months

Results: City B implemented a full depth reclamation program for rehabilitating its deteriorated streets. The process involved pulverizing the existing pavement and mixing it with cementitious materials. The reclaimed material was then compacted and topped with a new asphalt layer. The full depth reclamation technique proved to be an efficient and sustainable solution for rehabilitating multiple streets within a short timeframe.

-

Case Study 3: County C Road Reconstruction

Location: County C

Project Size: 5 miles of road

Duration: 2 months

Results: County C selected full depth reclamation as the preferred method for reconstructing a deteriorating road. The existing pavement was pulverized and mixed with cement and other additives to enhance strength and durability. The reclaimed material was then compacted and overlaid with a new wearing surface. The project resulted in a strong and long-lasting road, while also minimizing the environmental impact and reducing construction time.

These case studies demonstrate the effectiveness of full depth reclamation in rehabilitating old roads and improving their longevity. With its cost-effectiveness and sustainable approach, full depth reclamation is becoming an increasingly popular choice for road rehabilitation projects.

Common Issues and Challenges in Full Depth Reclamation

Reclamation:

- One of the main challenges in full depth reclamation is the process of reclaiming old or deteriorated pavement. This involves removing the existing pavement layer and recycling it to create a new base layer. However, this process can be time-consuming and labor-intensive.

- Another common issue with reclamation is the quality of the reclaimed materials. The quality of the materials can vary depending on the condition of the existing pavement and the recycling process. It is important to ensure that the reclaimed materials meet the required specifications for use in the new base layer.

Full Depth:

- Full depth reclamation involves recycling the entire pavement structure, including the base layer and subbase layer. This can be challenging as it requires a thorough understanding of the existing pavement structure, as well as the proper equipment and techniques for recycling the materials.

- Another issue with full depth reclamation is the potential for inadequate compaction. The recycled materials need to be properly compacted to ensure a stable and durable base layer. This requires careful monitoring and adjustment of compaction equipment during the construction process.

Depth:

- The depth of the reclamation process can vary depending on the condition of the existing pavement and the desired outcome. In some cases, a shallow reclamation depth may be sufficient, while in others, a deeper reclamation may be necessary. Determining the appropriate depth can be a challenge and requires a thorough assessment of the pavement structure.

- Another challenge with depth in full depth reclamation is the potential for damage to underlying utilities or structures. Excavating deeper layers of pavement may increase the risk of encountering buried utilities or compromising the integrity of nearby structures. Proper planning and coordination with utility companies and engineers are essential to minimize these risks.

In conclusion, full depth reclamation is a complex process that presents various issues and challenges. It requires careful planning, assessment, and execution to ensure a successful outcome. By addressing these common issues and challenges, full depth reclamation projects can achieve the desired results of creating a durable and sustainable pavement structure.

Future Trends and Innovations in Full Depth Reclamation

Full Depth Reclamation (FDR) is a widely used technique for rehabilitating and reconstructing roads and pavements. As technology continues to advance, new trends and innovations are emerging in the field of FDR, aiming to improve its effectiveness and sustainability.

One of the future trends in FDR is the use of advanced materials. Traditional FDR involves pulverizing the existing pavement materials, but researchers are now studying the potential of incorporating additives such as cement, lime, or fly ash to enhance the strength and durability of the reclaimed material. These additives can help create a more stable base for the new pavement, reducing the need for additional materials and improving the overall performance of the road.

Another innovative trend in FDR is the adoption of more environmentally friendly techniques. With growing concerns about sustainability, researchers are exploring ways to minimize the environmental impact of FDR processes. This includes recycling the existing pavement materials on-site, reducing the need for transportation and the consumption of new materials. Additionally, alternative energy sources such as solar or wind power can be used to power the machinery used in the reclamation process, further reducing the carbon footprint of the project.

The future of FDR also involves advancements in technology and automation. As digitalization becomes increasingly prevalent in construction industries, FDR processes can benefit from technologies such as advanced sensors, drones, and machine learning algorithms. These technologies can be used to gather data and provide real-time feedback on the quality and performance of the reclaimed materials, allowing for more accurate and efficient construction practices.

Furthermore, the future of FDR may involve the integration of smart infrastructure systems. With the rise of the Internet of Things (IoT), roadways and pavements can be equipped with sensors and communication devices that collect data on traffic patterns, road conditions, and pavement performance. This data can be used to optimize the design and maintenance of FDR projects, leading to safer and more durable roadways.

In conclusion, the future of Full Depth Reclamation is filled with exciting trends and innovations. Advanced materials, sustainability practices, technological advancements, and smart infrastructure systems are all shaping the future of FDR, aiming to create more durable and cost-effective roadways.

Question-answer:

What is Full Depth Reclamation?

Full Depth Reclamation (FDR) is a pavement rehabilitation technique that involves recycling existing pavement materials. It is an environmentally friendly and cost-effective method used to repair and restore deteriorated roads and pavement surfaces.

How does Full Depth Reclamation work?

Full Depth Reclamation works by pulverizing the existing pavement and mixing it with additives such as cement, lime, or asphalt emulsion. This mixture is then compacted and regraded to create a new base layer. The recycled pavement materials are strengthened and stabilized, resulting in a durable and long-lasting road surface.

What are the advantages of Full Depth Reclamation?

Full Depth Reclamation offers several advantages. It reduces the need for traditional methods of pavement reconstruction, which saves time and money. It also reduces the amount of waste generated from old pavement materials, making it an environmentally friendly option. Additionally, FDR creates a strong, stable road surface that can withstand heavy traffic and harsh weather conditions.

Is Full Depth Reclamation suitable for all types of roads?

Full Depth Reclamation is suitable for various types of roads, including rural roads, urban streets, and highways. It can be used on both flexible and rigid pavements. However, the applicability of FDR depends on factors such as the condition of the existing pavement, the availability of suitable additives, and the desired level of rehabilitation.

What is the lifespan of a road treated with Full Depth Reclamation?

The lifespan of a road treated with Full Depth Reclamation can vary depending on various factors, such as traffic volume, climate conditions, and maintenance practices. However, properly designed and constructed FDR projects can have a lifespan of 15 to 20 years or more. Regular maintenance and timely repairs can further extend the lifespan of the road.